- The average company spends nearly half of every dollar that it earns on production

- In the past, companies focused primarily on manufacturing and quality improvements to influence their supply chains

BASIC OF SUPPLY CHAIN

The supply chain has three main links :

- Materials flow from suppliers and their "upstream" suppliers at all levels

- Transformations of materials into semifinished and finished product through the organization's own production process

- Distribution of products to customers and their " downstream" customers at all levels

Organization must embrace technologies that can effectively manage supply chains

- PLAN

- A company must have a plan for managing all the resources that go toward meeting customers demand for products or services

- SOURCE

- Companies must carefully choose reliable suppliers that will deliver goods and service required for making products.

- MAKE

- This is step where companies manufacture their products or service. This can include scheduling the activities necessary for production , testing, packaging and preparing for delivery.

- DELIVER ( Logistic)

- Companies must be able to receive orders from customers, fulfill the orders via a network of warehouses , pick transportation companies to deliver the products and implement a billing and invoicing system to facilities payments.

- RETURN

- This is typically the most problematic step in the supply chain. Companies must create a network for receiving defective and excess products and support customers who have problems with delivered products,

|

| Factors Driving Scm |

VISIBILITY

- VISIBILITY - more visibility models of different ways to do things in the supply chain have emerged . High visibility in the supply chain is changing industries, as Wal- Mart demonstrated

- SUPPLY CHAIN VISIBILITY - the ability to view all areas up and down the supply chain

- BULLWHIP EFFECT - occurs when distorted product demand information passes from one entity to the next throughout the supply chain

- Supply chain visibility allows organizations to eliminates the bullwhip effect

- to explain the bullwhip effects to your students discuss a product that demand does not changes such as diapers . The need for diapers is constant , it does not increase at christmas or in the summer, diapers are in demand all year long . The number of newborn babies determines diaper demand and that number is constant.

- Retailers order diapers from distributions when their inventory level falls below a certain level , they might order a few extra just to be safe

CONSUMER BEHAVIOUR

- Company can respond faster and more effectively to consumer demands through supply chain enhances

- once an organization understands customer demand and its effect on the supply chain it can begin to estimate the impact that its supply chain will have on its customers and ultimetaly the organization performance

- Demand planning software - generates demands forecasts using statistical tools and forecasting techniques

- Supply chain planning (SCP) software -uses advanced mathematical algorithm to improve the flow and efficiency of the supply chain

- Supply chain execution (SCE) software - automates the different steps and stages of the supply chain

- SCP and SCE both increase a company's ability to compete

- SCP depends entirely on information for its accuracy

- SCE can be as simple as electronically routing orders from a manufactures to a supplier

|

| SCP and SCE in the supply chain |

Speed

Three factor fostering speed

Supply Chain Management success Factors

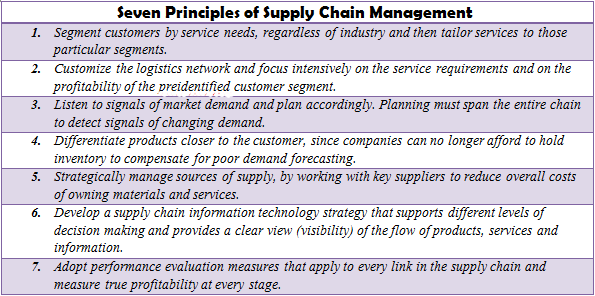

SCM industry best practices include :

- Make the sale to suppliers

- Wean employees off traditional business practices

- Ensure the SCM system support the organization goals

- Deploy in incremental phases and measures and communication success

- Be future oriented

SCM SUCCESS STORIES

To reasons why more executive are turning to SCM to manage their extended enterprise

- Numerous decision support system (DSSs) are being built to assist decision makers in the design and operation of integrated supply chain

- DSSs allow managers to examine performance and relationship over the supply chain and among

- Suppliers

- Manufacturing

- Distributions

- Other factors that optimize supply chain performance

TQ :)

No comments:

Post a Comment